Our holistic approach to engineering, manufacturing, and SCM

Nelson Miller Group provides winning solutions from design to delivery.Who we are

NMG partners with organizations to bring their industrial, IoT, lighting, medical, telecommunications, consumer, and aerospace products to life. We solve your most complex challenges in engineering design, manufacturing, and supply chain management. We take pride in developing relationships with customers and suppliers worldwide to deliver custom solutions that create value for all involved.

Our core values

We strive to be our customers’ partner of choice, helping them imagine more possibilities and unlock greater potential for their manufactured products. With this vision in mind, and recognizing that our supplier relationships are key to achieving it, we keep the following core values at the center of everything we do:

Customer commitment

We are committed to our customers' success by providing only the best service in everything we do. We believe speed, responsiveness, consistency, and flexibility are required to properly serve our customers.

Empowerment

We empower our people to utilize their creativity and talent to create success for our customers and themselves. We foster optimism, encourage ambition, and create a culture of ownership and accountability.

Integrity

We always act with integrity and transparency. We build trust internally and externally by always doing the right thing for the well-being and safety of our team members and the success of our customers. We say what we do, and we do what we say.

One team, one goal

We believe our success is only possible when everything we do is centered around one team and one goal. Our success comes when we all win together.

Continuous quality

We design, implement, and monitor reliable solutions that consistently deliver products and services at the highest standards. We strive to continuously improve our relationships, products, services, and selves.

NMG through the years

1930s to 1950s—nameplates and dials

Miller Dial was founded in 1937 and began by making luminescent dials for the Southern California Aerospace market. In the 50s, our sister division, Wilson-Hurd, became the “faceplate” for American Meter. To this day we continue to provide to these same customers, as well as many other world-class companies, such as Coleman.

1960s—plastic and vinyl labels

In the 60s, plastics like vinyl became available. The lighter weight and ease of cutting had customers clamoring for these innovative products. Nelson Nameplate began providing warning labels to Boeing. Soon after, Hunter Engineering decided to integrate a Nelson overlay into one of their balancers. These materials continue to improve and are used by hundreds of customers including the Irritrol group of Toro.

1980s—membrane switches

The flexibility of plastics and the development of conductive inks led to the invention of the membrane switch. Our first switches were used in airplane seats to adjust the headset sound volume. Today, the membrane top surface may be made of silicone rubber, like this one for Haas Automation, but the results are the same: easy-to-use human-machine interfaces!

1990s—supply chain services

In 1998, Visiontech Solutions Group (later known as Chainlogix) was founded to solve OEMs’ complex sourcing and supply chain challenges. We became the outsourced manufacturing and supply chain solutions partner for many OEMs and SMEs. With over 200 supplier relationships and capabilities across the full spectrum of global supply chain management, customers get unparalleled supply chain reliability, impactful cost reduction, and superior innovation.

2000s—touch, injection molding, and piezo

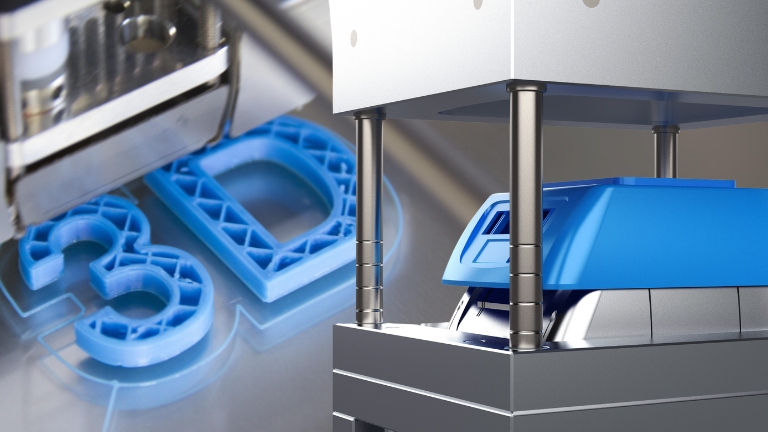

In the new millennium, we helped Edwards Lifesciences develop a touch interface for a new clinical platform and provided the PCB and integrated silicone rubber keypads for a future division of Bayer. We manufactured several Piezo switches for use in harsh environments, including this one for Midcom. Chainlogix began providing outsourced manufacturing and SCM for injection molded plastics, LEDs, metal parts, and touch screens.

2010s—assemblies

As Miller Dial and Nelson Nameplate merged in 2011, we began offering complete assemblies for our customers. We started by building the user interface and controller for a commercial Waring blender. We were also contracted to redesign and fully manufacture the UV nail dryer system for OPI. In 2017, we added Wilson-Hurd to the Nelson-Miller family, deepening our expertise in electronic controls and HMI components.

Early 2020s—printed electronics, IoT, and pandemic response

With the rise of printed electronics, we’ve made wi-fi receivers, digital TV antennas, and medical devices like the INeedMD sensor pictured. In the IoT realm, we’ve created housings for a power control/thermostat system by Powerley and lighting controls by Lutron and Deako. Our state-of-the-art ERP, SCM expertise, and safety stocking programs enabled us to deliver 25 million+ pieces without interruption during the pandemic.

Today and into the future

In 2023, Nelson Miller and Chainlogix joined forces to create Nelson Miller Group. Our new name honors our 85-year legacy and celebrates our expanding portfolio of industries, domestic engineering expertise, supply chain management services, and global footprint. In July 2023, Injection Works was acquired by NMG—greatly increasing our plastic injection molding capabilities within the United States. Looking to the future, the NMG team remains dedicated to integrity, customer care, and staying at the forefront of technology and industry trends.

Case studies

See real-world examples of how NMG has helped customers across the full spectrum of the supply chain, from design to delivery.

Read our blog!

Access industry updates, helpful how-tos, engaging infographics, and other resources for engineers and supply chain professionals on the NMG Blog.

Get in touch!

We can’t wait to create winning solutions with you.

For general inquiries, please fill out this form and our team will be in touch shortly.