Our process for supply chain outsourcing

Nelson Miller Group listens carefully to your needs and communicates with honesty and transparency, so you always know where your project stands and what’s coming next.

Each project starts with a clean slate.

We approach each new project with a listening ear, formulating truly customized solutions that simplify supply chain management, mitigate supply chain risks, improve the bottom line, and add value for your organization.

Discuss

Our customers are driven by a similar desire—to deliver the best product, for the best price, at the right time. Once we start to dig under the surface, however, each customer's needs become increasingly different. Many tell us they have an interest in a combination of the following factors:

- Solving an engineering challenge

- Reducing costs

- Accessing new or additional talent

- Farming out activities that others can do better or more easily

- Increasing flexibility in their business model

- Addressing quality and lead time issues

Whatever your goals, NMG understands that each customer is unique. Starting out with an initial understanding of what drives you and what pain points we can help resolve provides a framework for more detailed discussions and solution development.

At this step—non-disclosure agreement

Discover

Over the course of several meetings, we dig deep into the details to ensure a thorough understanding of your requirements, specifications, and any constraints you may have.

Who?

Your Account Exec, your team (lead buyer, supply chain expert, engineer, executive)

What?

Identify your organization's goals and pain points—and how we can help

When?

Establish a timeline that suits your needs

Why?

Understand your challenges (causes, costs, repercussions, and their extent)

How?

Review of your product or part, design/engineering, and manufacturing process, including drawings, golden samples, BOMs, assembly, etc.

At this step—account creation

Develop

Informed by our prior conversations, the NMG team creates an initial proposal detailing the combination of products and services that we feel best suits your organization.

We leverage our knowledge of the industry, in-house engineering design expertise, broad-reaching supplier partnerships, and the most up-to-date best practices to craft a business plan unique to your company.

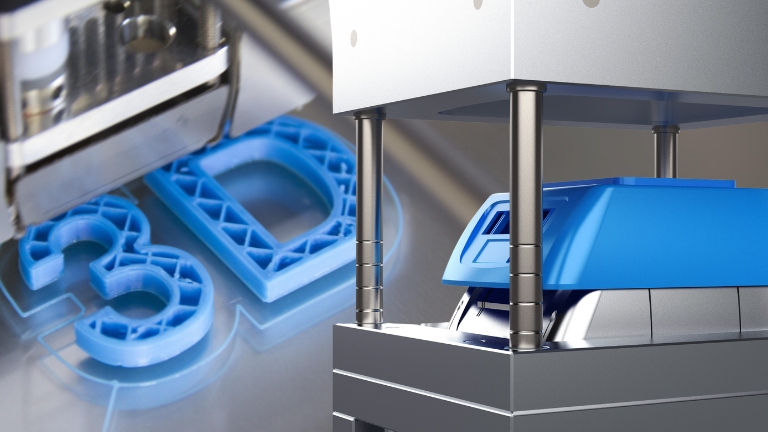

At this point, the project undergoes any necessary DFM work including design, review, modification, and approval.

As with the rest of the process, this isn't a one-sided conversation. NMG works with you to co-create the solution that works best for your business and adds the most value during implementation and beyond.

At this step—first sample, article, or prototype

At this step—first purchase order

Deliver

Once we've agreed upon the best approach, we're ready to move into production. This is where we take our partnership to the next level.

Quality assurance

This includes approval of the final product, oversight of regular testing and inspection, and regulatory submission as applicable.

Manufacturing

We coordinate a pilot run and scale-up, assembly (if needed), and packaging. Of course, ongoing quality control is paramount and included in our services.

Customer care

Through regular communication and visits from your NMG Account Executive, you are kept abreast of important updates and receive analytics and reporting on the KPIs that are important to you. We continually seek to optimize your product and process, ensuring we maintain and increase our value as part of your team.

At this step—freight forwarding and receiving

Ready to start the conversation about supply chain outsourcing?

Case studies

See real-world examples of how NMG has helped customers across the full spectrum of the supply chain, from design to delivery.

Read our blog!

Access industry updates, helpful how-tos, engaging infographics, and other resources for engineers and supply chain professionals on the NMG Blog.

Get in touch!

We can’t wait to create winning solutions with you.

For general inquiries, please fill out this form and our team will be in touch shortly.