NMG—rugged switch manufacturer

Elevate your interface with rock-solid ruggedization: Where style meets reinforced substance.

Rely on Nelson Miller Group’s switch manufacturing expertise to help you design and build the rugged switch you need.

Rugged switches—built for harsh environments.

There are as many definitions of a switch’s ruggedness as there are industries and applications where they are used. A medical device may prioritize resistance to cleaning materials; a military switch requires shielding against Electromagnetic Interface (EMI), and protection against a harsh environment may be essential in an industrial setting.

Nelson MIller Group (NMG) considers three dimensions to define how to achieve the rugged switch you desire: 1) the end-use environment (or environmental elements), 2) the integration of the switch in your device, and 3) the operator’s interacti`on with the switch (actuation volume and force, abuse, vandalism).

Achieving a certain level of ruggedness will impact the cost of your device. NMG engineers help you find the right balance between cost and performance so that your switch can last the full length of its desired lifetime. This is one of the reasons we are the rugged switch manufacturer of choice for Carrier and its line of industrial coolers.

How can a protective coating deliver a rugged switch?

One common step is to add an outer layer as a protective topcoat. It’s a transparent layer made of either polyester (PET) or polycarbonate (PC).

PET tends to be preferred for membranes; it has excellent corrosion and wear resistance, resistance to oil and most solvents, low gas and water vapor permeability, and an ability to withstand temperatures between -700oC and -1200oC.

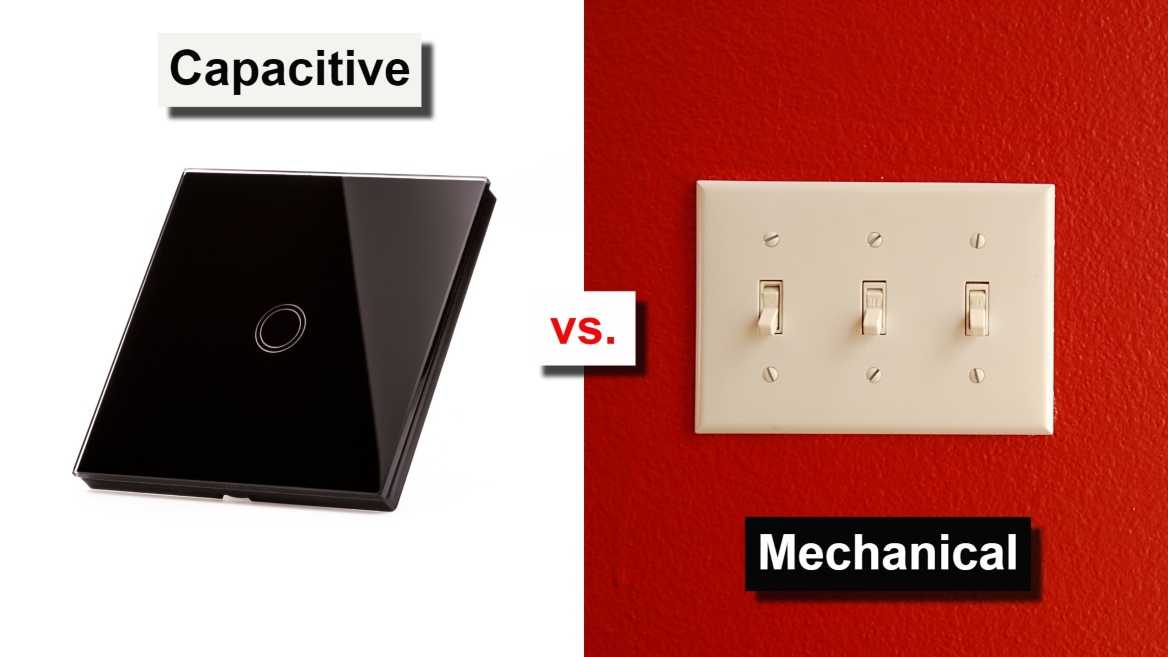

Polycarbonate (PC) is a strong and stiff plastic that has high impact resistance and transparency, is stable to light (but not UV-resistant), and has stable mechanical properties across a wide temperature range, as well as dimensional stability, electrical properties, and flame retardancy. PC has a lower fatigue strength (it can more easily produce stress cracking); therefore, PC will be used less for membrane switches but is a good fit for capacitive switches.

Will your switch be exposed to microbes, moisture, water, high/low temperatures, dust, UV rays, contaminants, vibrations, etc.? Each protective coating has its distinct advantages mitigating against multiple conditions at once. For example, the Dupont Teijin Films (DTF) offers 24 different types of polyester films for printed and flexible electronics under the Melinex, Kaladex, or Mylar brands.

How to shield your switch to maintain signal integrity

The defense and aerospace industries, and some industrial settings, demand a very high immunity against external factors like electrical signal interference, external electromagnetic noise, cross-talk, or radio frequency interference. Switches can be built with ESD (Electrostatic Discharge), EMI (Electromagnetic Interference), RFI (Radio Frequency Interference) shielding features:

- Mechanical switches. Special gaskets and o-rings provide mechanical design flexibility for cushioning and sealing between mated surfaces.

- Membrane switches. A layer can be made of conductive silver ink, carbon ink, laminate, tape, or foil.

- Capacitive/resistive switches. The use of either fine wire mesh or transparent thin film conductive coatings to reduce or eliminate the effects of EMI.

Additional solutions for capacitive touch switches

The use of thermally tempered glass protects the touch sensors from weather conditions (even extreme temperatures) without affecting the functionality of the user interface. PC films can also be added as an outer layer and have become very popular for cell phones and monitors as a protective anti-scratch film.

Finally, there is an opportunity to add an optical bonding step while building your touch switch. Optical bonding is the process of applying a clear resin to fill the gap between touch screen display and the protective glass. This prevents moisture and dirt from gathering, avoids condensation, and improves resistance to temperature fluctuations and mechanical stress.

How do NMG engineers design rugged switches?

Our engineers have formidable experience in designing your switch for IP ratings 65, 67, and 68. There are three areas where design can make a big difference in developing a rugged switch:

- The design of the seal(s) and /or the enclosure for the switch:

- Add a gasket or perimeter seal frame design.

- Add o-rings and/or a sealed panel with a waterproof membrane outside of the lever for mechanical switches.

- Add an edge gasket between the cover edge and the mounting box, or a heat-sealed adhesive that removes all air trapped between the layers.

- The choice of material and manufacturing steps:

- Proper metal selection for the button and faceplate of the mechanical switch can increase ruggedness. Stainless steel has superior strength, aluminum is rust-proof, etc.

- Proper bonding resin/tape selection based on the nature of the material to which the membrane switch will bond.

- The type of tail for electronic switches—will it need to bend and crease?

- Proper selection of the types of board: thin printed circuit board, a flexible printed circuit, or a rigid circuit board.

- Proper laminating technique for superior adhesion strength and consistency.

- Understanding how actuation over time will impact performance, for example:

- We advise against features such as embossing and tactile feedback on a membrane switch planned to have high actuation. These features weaken the membrane and can lead to fracture and crack, causing premature switch failure.

- The high and frequent variation of temperatures leads to expansion/contraction rates that cause sheer stress at the interface between the membrane and its back metal plate.

The piezo switch solution

Piezo switches are solid-state devices, meaning they have no moving parts. Unlike traditional mechanical switches that rely on physical contacts, piezo switches operate by the piezoelectric effect. This lack of moving components makes them inherently more durable and less prone to wear and tear. They're also typically sealed against moisture, dust, and other contaminants. This makes them well-suited for use in harsh environments, such as industrial settings or outdoor applications.

More importantly, piezo switches offer unmatched resistance in two key areas:

- Piezo switches can withstand high levels of vibration and shock, which is crucial in applications where equipment may be subject to constant movement or mechanical stress. This makes them ideal for use in machinery, vehicles, or other settings where vibrations are common.

- Piezo switches can operate reliably across a broad temperature range. This flexibility makes them suitable for both hot and cold environments, making them a preferred choice in industrial and outdoor applications where temperature fluctuations are common.

These highly customizable (shape and size) switches also offer great flexibility in HMI design. You may not see as many piezo switches as other switch types because they are more costly to manufacture; nonetheless, they're an incredible solution when protection and reliability in certain environments outweigh cost limitations.

Ready to start a project today?

Case studies

See real-world examples of how NMG has helped customers across the full spectrum of the supply chain, from design to delivery.

Read our blog!

Access industry updates, helpful how-tos, engaging infographics, and other resources for engineers and supply chain professionals on the NMG Blog.

Get in touch!

We can’t wait to create winning solutions with you.

For general inquiries, please fill out this form and our team will be in touch shortly.

.jpg)