Custom touch screens and touch switches manufacturer

Precision, efficiency, and innovation in every touch

Count on Nelson Miller Group to provide cutting-edge touch solutions.Ubiquitous tech, infinite possibilities

The first patent on touch screens was issued in 1969, and major applications entered the market in the 1980s. However, they really became mainstream when Apple released the first iPhone in 2007. Touch screens are now an integral part of many human-machine interfaces and have become prevalent in our daily lives. We've all tapped, swiped, scrolled, pinched, barely touched, or even waved when interacting with a touch screen.

NMG works with numerous types of touch screen technologies and can help select and design the right technology for your touch screen:

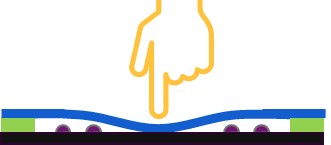

- Resistive touch: switches and screens

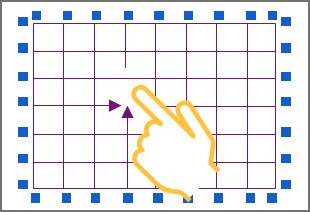

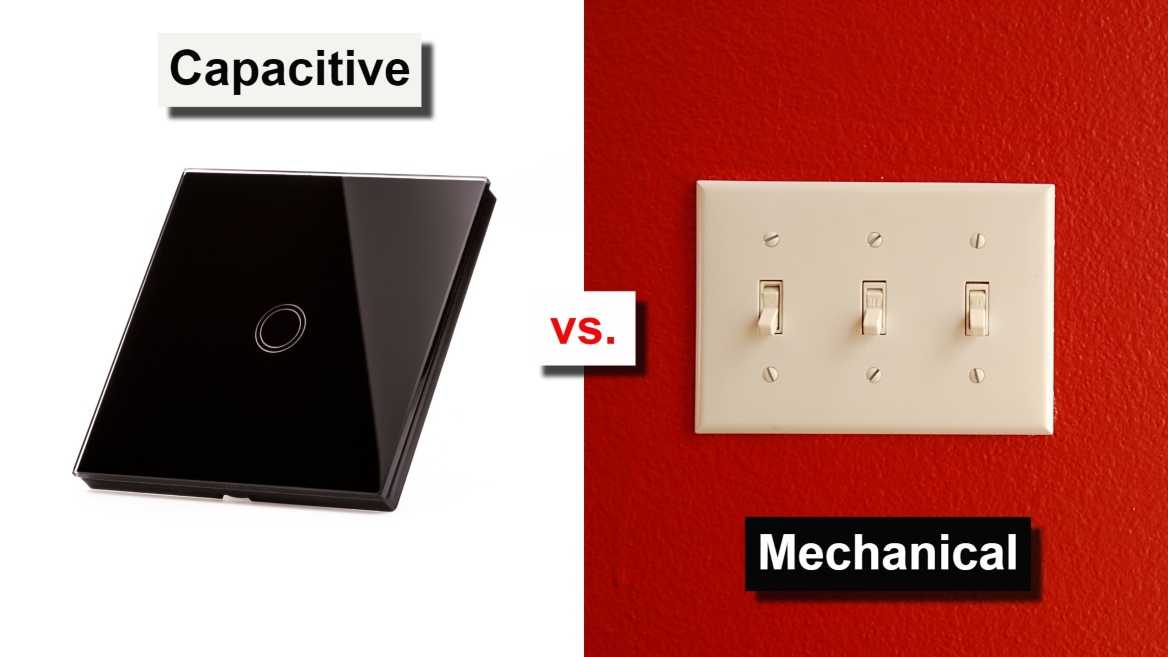

- Capacitive touch switches and screens (PCAP and SCAP)

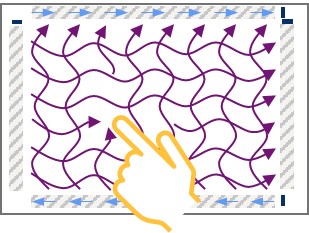

- Surface acoustic wave (SAW) touch screens

- Infrared (IR) touch screens

Click an option below for additional information about each technology.

How do touch switches work?

There are three components that work together in a touch screen capability: the touch sensor, the controller, and the software.

The controller plays a crucial role in determining the “touch” location. It extracts data from the sensor to pinpoint the precise touch location, which is subsequently transmitted to the software for response. Despite the complexity of this process, it unfolds in mere nanoseconds in real-time.

Resistive touch and capacitive touch technologies apply to a switch or a screen interchangeably. There are other technologies that can be applied specifically to touch screens such as projected capacitive touch (PCAP), surface capacitive touch (SCAP), surface acoustic wave (SAW), infrared touch (IR) or optical imaging touch. Our engineers help you select and design the right technology for your touch screen.

Unmatched solutions in touch screen design and manufacturing

Every touch screen, touchpad, and touch switch NMG designs, produces, and delivers is custom-made to match with extreme precision the form, fit, and function you desire. The versatility of touch screens and touch switches, combined with our design engineering skillset, help you achieve your specific visual design to create the perfect interface.

Our touch screens possess a self-contained system that gives flexibility to the design of your overall product. What separates NMG from other manufacturers is our ability to design, manufacture and deliver a custom full system from components, to circuitry, overlays, firmware and an array of customization options. We have over thirty years of experience in controls and HMI and have built custom switches and touch screens that others considered impossible to make.

NMG doesn’t produce standard, off-the-shelf touch screens; many other organizations offer these products if you only need a standard-sized display (7" to 27”). NMG’s specialty is 1) in the manufacturing of your touch screen in a custom size and/or shape, and 2) the integration of an off-the-shelf screen in the manufacturing of a custom control interface or HMI.

Features for your custom touch screen

NMG has the engineering expertise to incorporate many features in your custom touch switch, including proximity sensors, sub-surface sensing, flexible circuits, connector options, shielding for environmental protection, custom covers, curved surfaces, custom color matching, graphic overlays, uniquely shaped and sized display windows, smart wake-up functions, dead front, etc.

Tap into more possibilities with NMG.

- Augment the durability of your touch switch.

- Enhance your interface's readability and aesthetics.

- Ensure signal integrity.

- Full system design and layout.

- Optimize light distribution.

Selecting the right manufacturer and partner

When evaluating your touch screen manufacturer, you should consider these factors that drive the quality of your final product, reduce complexity for you, cut your costs, and increase your speed to market:

- In-house engineers providing critical thinking and years of experience to every project.

- Experience in complex user interface assemblies.

- Custom sensor placement and programming.

- Expertise in custom extreme-environment touch switches.

- High competency in illumination and backlighting.

- Rigorous production tolerances.

- Overlay customization abilities.

Ready to start a project today?

Case studies

See real-world examples of how NMG has helped customers across the full spectrum of the supply chain, from design to delivery.

Read our blog!

Access industry updates, helpful how-tos, engaging infographics, and other resources for engineers and supply chain professionals on the NMG Blog.

Get in touch!

We can’t wait to create winning solutions with you.

For general inquiries, please fill out this form and our team will be in touch shortly.