Quality product manufacturing services and assembly

Nelson Miller Group’s in-house and contracted production facilities follow rigorous processes to ensure your product’s integrity and protect your company’s reputation.Trust NMG to diligently manage the intricacies of quality manufacturing, quality assurance, and assembly.

Our disciplined team pays critical attention to your products and needs. At every step of the production process, we vet, plan, test, organize, and optimize. From raw materials to finished products and factory selection to freight forwarding, NMG meets your precise requirements and quality criteria.

When it's beyond your realm of expertise

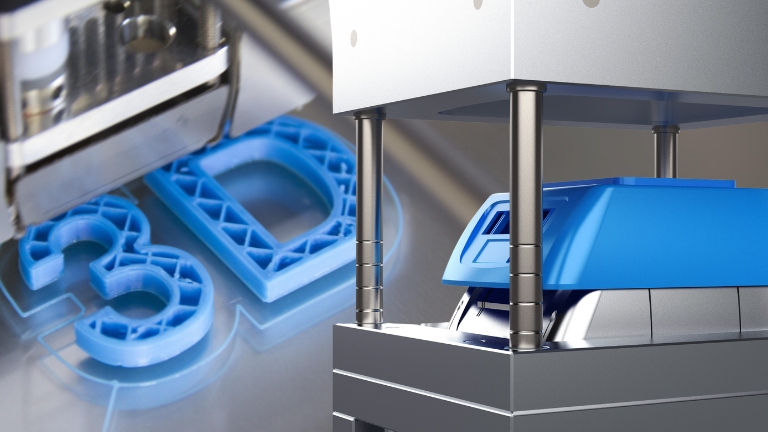

What separates NMG from many other strategic outsourcing partners is our ability to tackle some of the most unique needs and find the perfect-fit solution. You may need unique performance attributes for your product. We’ve managed the outsourced manufacturing of products like police body cameras and controls for refrigeration systems that require extreme ruggedness to withstand hostile weather conditions, extensive use, and even vandalism. We’ve completed highly complex integration of hardware into plastic injection-molded components, as well as multiple IoT devices into a box-build.

Your expertise may be in firmware development or consumable products but not in product manufacturing. We’ve helped a leading innovator in wide-area network technologies launch a gateway router, an advertising placement company deploy 300 industrial-grade, interactive kiosks in a major metropolitan city, a major nail polish manufacturer deliver a UV dryer to complement their core product offering, and the world’s leading provider of in-flight wi-fi equipment complete a printed-electronic antenna assembly.

Many manufacturers aren’t equipped for the level of complexity of your project. NMG finds the solutions for you.

When you're struggling to source critical, custom parts affordably

Maybe your team is stretched thin; you may lack resources in time, people, or budget. We consolidate your AVL and offer a single point of contact, removing the complexity of manufacturing sub and full assemblies. We have helped customers avoid sole sourcing and high-risk exposure by delivering an end-to-end supply chain management solution with alternate/second sourcing. Companies like ABB and Acuity rely on NMG for these supply chain services.

NMG supports your strategic sourcing and outsourcing, from assessing your production needs to contract negotiation and long-term supplier management. We can help you navigate the sometimes complex and confusing path to effective and efficient global cost-reduction manufacturing. Manufacturers that have implemented global sourcing have leaped ahead of the pack in reducing costs, accelerating speed-to-market, and improving product quality. For example, we managed the strategic sourcing of large springs in Asia for a garage door manufacturer that could not explore global opportunities on its own.

Ready to start a project today?

Case studies

See real-world examples of how NMG has helped customers across the full spectrum of the supply chain, from design to delivery.

Read our blog!

Access industry updates, helpful how-tos, engaging infographics, and other resources for engineers and supply chain professionals on the NMG Blog.

Get in touch!

We can’t wait to create winning solutions with you.

For general inquiries, please fill out this form and our team will be in touch shortly.