Successful OEM supply chain management starts here.

Nelson Miller Group supplements your existing infrastructure with our knowledge, ERP, and relationships to create a reliable and transparent supply chain.Make your supply chain stress-free.

Utilizing our own assembly and manufacturing sites and our extensive partner network, we can source and manufacture the major components of any device. NMG is an expert at providing you with custom electronic, electromechanical, plastic, rubber, and metal components. We rely on our state-of-the-art ERP, our global team at your source and destination markets, and 30 years of experience in demand planning and inventory control to take the stress out of your supply chain and ensure there are no disruptions. We have the agility to coordinate with multiple sources to customize a supply chain solution that accommodates the 3PL, warehouses, freight forwarding, and other infrastructure you may already have in place.

With so many ways to approach supply chain management and logistics, it can be difficult to know which strategy (or combination of strategies) is best for your organization. NMG approaches every customer conversation with an open mind, creating solutions that are customized to the unique needs of each business. From sourcing a single electronic component or metal part to managing your entire supply chain, we have the tools and know-how to make your project a success.

Electronics

We help our customers manufacture precise, custom components at a highly competitive price point. When it comes to electronic components, we have extensive experience in the processes of designing, assembling, producing, and testing electronic components as well as PCB.

You can rely on NMG for the manufacturing of your passive and electromagnetic components such as air core coils, wireless coils, SMD inductors, DR inductors, common mode chokes and filter inductors, high-frequency transformers, resistors, thermistors, and other electronics. In addition to strict inspection of the raw materials used, our manufacturing sites have independently developed advanced production machines featuring automatic winding, soldering, packaging, and testing. Our world-class partners' R&D and engineering teams allow NMG to deliver highly customized magnetics design, short lead time, consistent and on-time delivery, extraordinary PPV, and product reliability.

Most electronic parts and devices require a circuit board. NMG provides solutions in the manufacturing of traditional printed circuit boards but also in more advanced circuitry such as flexible and printed electronics. These more advanced technologies allow you to address challenges you may face with regard to small size, lightweight, flexible form, ease of integration and low cost.

Electromechanical devices

With our in-house engineering expertise, NMG can integrate the electrical and mechanical demands of your device. We deliver box build assemblies that demand electrification, circuitry, controls and switches, connectors, wiring, lighting, sensors, and the like. Among our recent projects, we count products from simple rubber switches to connected IoT devices. Our work serves the medical, industrial, telecommunication, and consumer electronic industries.

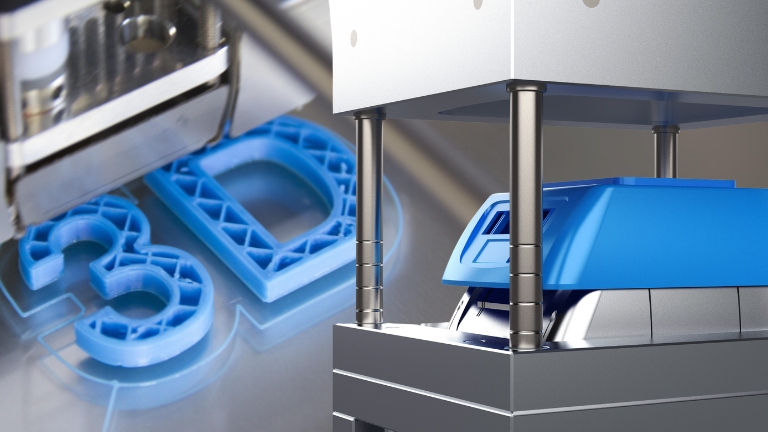

Plastic injection molding

Plastic injection molding is a key process in the production of electronic devices, medical instruments, automotive components, and consumer appliances. While plastics can offer practicality, flexibility, and lower production costs, careful attention must be paid to the design, resin selection, and mold creation. Therefore, you need a strong partner to deliver on all the benefits plastic injection has to offer. NMG oversees the manufacturing of custom buttons, cases, connectors, controls, covers, diffusers, enclosures, fittings, frames, handles, harnesses, housings, light fittings, o-rings, sockets, switches, and many more. Injection Works, a divsion of NMG, serves as our in-country authority for custom thermoplastc injection molding and related services.

Switches and keypads

Industrial, aerospace, medical, and consumer electronic OEMs come to NMG for their keypad needs. Our expertise in delivering the right tactile response and environmental resistance covers many types of products, including plastic, silicone rubber, UV, and ultra-thin keypads. We offer all types and configurations of keypads and keypad switches. PCBs, molded enclosures, and a wide variety of connection types available allow us to provide complete assemblies with a fast turnaround.

Lighting and LEDs

NMG has the resources to produce the lighting components for your electronic and electromechanical devices. Our expertise covers connectors, heat sinks, LED drivers, LED diodes, lenses, optical controls, reflectors, and wiring for your down lights, e-panels, shop lights, troffers, or track lights.

We also offer backlighting solutions, which are often used in controls and HMIs. With our advanced engineering and production techniques, NMG offers a real advantage with reduced production costs and superior performance of light-guided foils. We are fluent in the use of fiber optics for uniform backlighting and the design of electroluminescent (EL) backlighting solutions for membrane switches and other various customer applications by printing phosphors between two conductive layers.

Metal parts

Metal parts are unique to your industry and your product applications. NMG has expertise in numerous metal part manufacturing processes, including die casting, CNC machining, extrusion, 3D printing, rolling, punching, and stamping. We specialize in aluminum, brass, copper, zinc, steel, and iron materials when it comes to metal part manufacturing. Our metal part solutions have been applied to cabinets, casings, connectors, enclosures, fittings, frames, hinges, housings, wheels, rings, handles, brackets, mounts, racks, sockets, and springs.

Dials, overlays, and panels

With our extensive printing and fabrication capabilities, NMG offers detailed nameplates, overlays, and metal back panels to suit your project’s unique needs. Our plant pairs screen, litho, and digital printing techniques with a wide variety of materials to offer you a cost-effective and reliable product at a high volume. We deliver over 3 million dials, overlays, and panels annually, with design options like domed nameplates, embossing, selective texturing, colored LED windows, and hard-coating.

Ready to start a project today?

Case studies

See real-world examples of how NMG has helped customers across the full spectrum of the supply chain, from design to delivery.

Read our blog!

Access industry updates, helpful how-tos, engaging infographics, and other resources for engineers and supply chain professionals on the NMG Blog.

Get in touch!

We can’t wait to create winning solutions with you.

For general inquiries, please fill out this form and our team will be in touch shortly.