Infrared touch screen manufacturer

An invisible grid of light makes the slightest touch count.

Nelson Miller Group has the expertise to integrate infrared touch screen technology in your HMI device.

What is an infrared touch screen?

Infrared (IR) touch screens have been in use for several decades, with early implementations dating back to the 1980s. The technology relies on infrared light beams and sensors to detect touch input on the basis of light-beam interruption, or beam break. Engineers appreciate the technology for its simplicity, durability, and versatility in various applications.

IR touch screen devices are used most often for cash registers, desktop computer monitors, or information kiosks in public spaces like airports, shopping malls, and museums. They’re also used for interactive whiteboards in classrooms or offices, interactive displays in training rooms, and medical imaging devices.

NMG uses IR touch technology in healthcare for medical imaging workstations and patient information retrieval. The multi-touch-point capability allows for easy navigation between images and applications, as well as key image rotation and zoom in/out functions. NMG is more focused on smaller size applications than large information signage and display you will find in hotels, retail, or public areas.

How does an IR touch screen work?

The infrared touch screen works by detecting interruptions of infrared beams emitted by LEDs embedded in the frame around the touch screen overlay. An array of X-Y infrared LEDs and photo detector pairs around the edges of the screen form a grid pattern. When the screen is untouched, the infrared light beams travel undisturbed from the LEDs to the sensors. The main components are:

- Infrared light source. An array of infrared light-emitting diodes (IREDs) is placed along the edges of the screen. These LEDs emit infrared light across the surface of the screen.

- Infrared sensors. These sensors (composed of phototransistors) detect any interruption or blocking of the infrared light caused by a touch on the screen, pinpoint the location of the touch, and send the touch coordinates to the controller.

- Controller. the controller processes the information from the sensors, determines the exact characteristics of the touch input, and then translates this data into a format that can be understood by the connected device.

- Display. The display is the image source. The IR touch frame is mounted around the perimeter of a display. LCD monitors or LED displays are the common choice.

The advantages of infrared touch screen technology

Ease of use. Anything can be used to register a touch. There is no need for a specific type of conductor.

Durability. Infrared touch screens are known for their durability because they have a glass or acrylic surface that can withstand physical impact and resist scratches. They also don’t require any special patterning on the screen, making them less susceptible to cracks and shatters. This makes them suitable for public and high-traffic environments.

Multi-touch and multi-user. Infrared sensor technology supports from 1 to 40 touch points (1, 6, 10, 16, 32, 40 touch points). Many popular digital signage devices feature 10 points or more. The number of touch points that can be triggered at once makes it possible to register motions like swipes and zooms, multi-finger gestures for complex inputs, and multiple people using the device simultaneously.

Wide range of sizes. It’s possible to produce small size screens of 10” up to 350”. It’s important to note that frame glass usually goes up to 42”; for larger screens, a frame without glass is typically used. We’ve seen sizes of 500" when creating video walls (multiple displays at once).

Outstanding image clarity. The ability to use large frame glass without any patterning means that the display’s brightness and image clarity are not affected by the sensors.

When to choose an infrared touch screen

Infrared touch screens are especially suitable for:

- Presentations, commercials, and digital signage when image clarity is of utmost importance.

- Applications where the screen needs to withstand dirt, debris, or liquids—such as wayfinding solutions or for point-of-sale applications.

- Large screen-size applications like interactive digital signage, kiosks, and collaborative workspaces.

- Activities demanding precise or complex gestures, such as drawing in graphic design.

- Frequent changes in seasons and climates. IR technology is unaffected by moisture and temperature variations. However, note that the equipment around and/or supporting the touch screen may require heating/cooling features.

Limitations of IR touch screens and possible remedies

High sensitivity. IR touch screens are incredibly sensitive. They can register the lightest touch or be incorrectly triggered if something falls or unexpectedly touches the screen. The build-up of dust, oil or grease on the screen can also cause malfunctions. However, they are easy to clean because of their flat surface and glass panel.

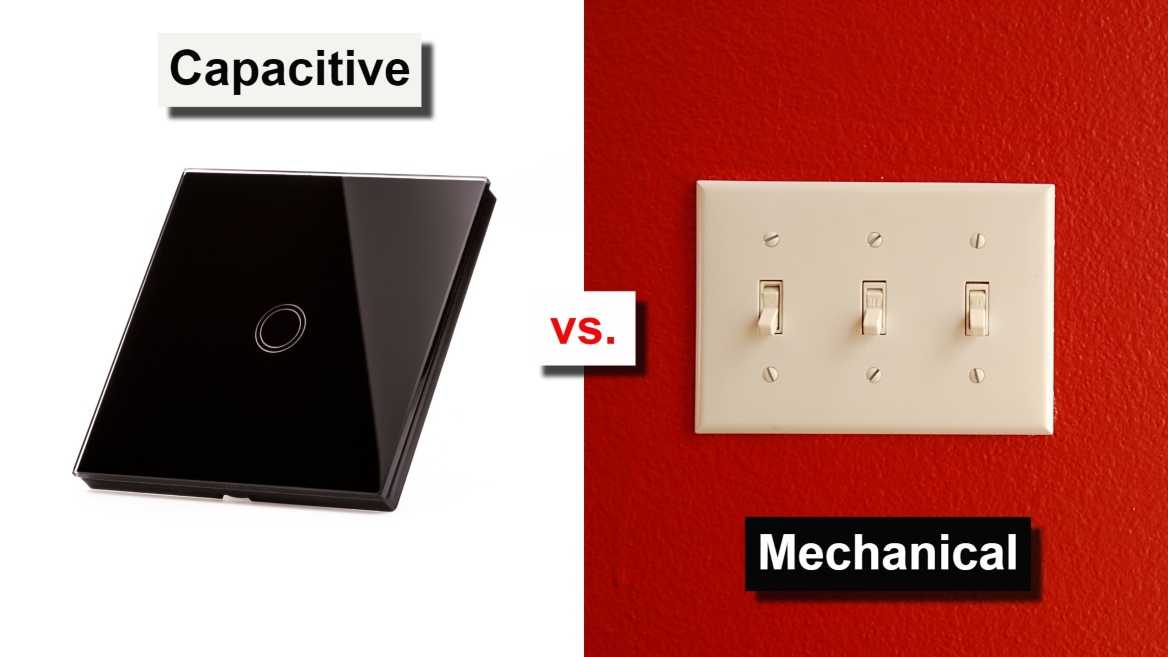

Display must be flat. Since IR touch screens are constructed on the principle of light interruption captured by sensors, curved displays will reduce accuracy and sensitivity—especially in the corners. If a curved display is required, capacitive or resistive touch technologies represent better solutions.

Light interference. The baseline infrared touch solution is not immune to sunlight. To address ambient light interference, especially sunlight, the following steps can help:

- Design the touch screen with adjustable sensitivity settings.

- Incorporate optical filters that specifically target the wavelengths associated with sunlight.

- Optimize the physical design of the touch screen enclosure to provide shade over the screen or use materials that reduce reflections and glare.

- Develop algorithms that specifically reject sunlight interference and implement them in the touch screen controller to filter out unwanted signals caused by sunlight.

Need for added protection against contaminants. IR technology in itself is not water- or dust-resistant, but careful design and selection of materials to protect the internal components can make an infrared touch screen more resistant. We recommend the use of gaskets and seals, a protective coating or laminate to the surface of the touch screen, and a perfectly sealed enclosure. These solutions can further protect your touch screen device without affecting touch sensitivity.

Ready to start a project today?

Case studies

See real-world examples of how NMG has helped customers across the full spectrum of the supply chain, from design to delivery.

Read our blog!

Access industry updates, helpful how-tos, engaging infographics, and other resources for engineers and supply chain professionals on the NMG Blog.

Get in touch!

We can’t wait to create winning solutions with you.

For general inquiries, please fill out this form and our team will be in touch shortly.